Search This Supplers Products:steel flangesCarbon steel pipe elbowssteel pipe teessteel pipe redcuerssteel pipe capspipe bends

Steel pipe bends material and caculating

Pipe fittings are necessary to join together pipes, or to change the direction of an existing pipe. Pipes and pipe fittings are made of a variety of materials, depending on the fluid or gas being transported. Most pipe fittings tend to be either threaded or able to slip over the pipes they connect. Whether you are using steel pipes of PVC pipes, a chemical solvent is required to create a seal between the pipe and the fittings.

Measure the required length of the pipe to be installed, keeping in mind the extra length required where the pipe will be inserted into the fitting. Mark this length on the pipe.

The pipe bending is used to change the direction of run of pipe.

It advantage is can match long distance transition requirements, so it is commonly that bends dimension according to customer design.

Materials

They are manufactured utilizing higher grade raw material, advanced machines and technologies.

Abrasion resistant: Ceramic lined, Ceramic tile, Bi-metal clad pipe bending, Rare earth alloy wear-resistant pipe bending

Carbon steel:

ASTM A234 WPB, ASTM A234 WPC, ASTMA42 WPL6, ASTMA42 WPL3, WP1. MSS-SP75, WPHY, WPHY 46, WPHY 52, WPHY 56, WPHY 60, WPHY 65, WPHY 70

DIN 1629 St37, RST37.2 St52, STPG38

Pipe fittings are necessary to join

together pipes, or to change the direction of an existing pipe. Pipes

and pipe fittings are made of a variety of materials, depending on the

fluid or gas being transported. Most pipe fittings tend to be either

threaded or able to slip over the pipes they connect. Whether you are

using steel pipes of PVC pipes, a chemical solvent is required to create

a seal between the pipe and the fittings.

Measure the required length of the pipe

to be installed, keeping in mind the extra length required where the

pipe will be inserted into the fitting. Mark this length on the pipe.

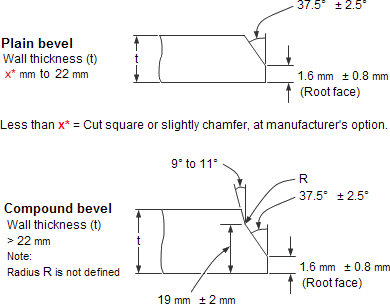

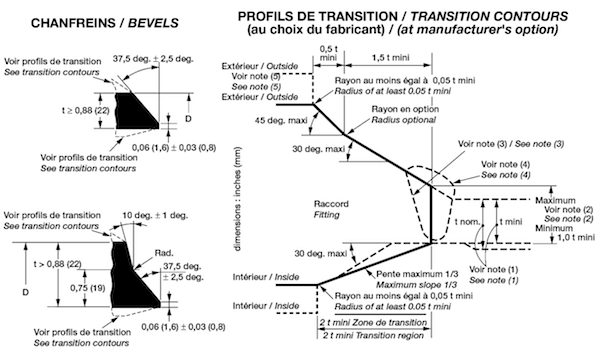

Beveled Ends

The ends of all butt-weld fittings are bevelled, exceeding wall thickness 4 mm for austenitic stainless steel, or 5 mm for ferritic stainless steel. The shape of the bevel depending upon the actual wall thickness. This bevelled ends are needed to be able to make a "Butt weld".

Beveled Ends

The ends of all butt-weld fittings are bevelled, exceeding wall thickness 4 mm for austenitic stainless steel, or 5 mm for ferritic stainless steel. The shape of the bevel depending upon the actual wall thickness. This bevelled ends are needed to be able to make a "Butt weld".Welding Bevel acc.to ASME / ANSI B16.9 and ASME / ANSI B16.28

ASME B16.25 covers the preparation of butt-welding ends of piping components to be joined into a piping system by welding. It includes requirements for welding bevels, for external and internal shaping of heavy-wall components, and for preparation of internal ends (including dimensions and dimensional tolerances).

Our in-hourse R&D team developed bevel ends equipment are good using in thickness 2mm to 20mm pipe fittings, guarantee high efficiency and high quality.

Send us your technical drawings

These weld edge preparation requirements are also incorporated into the ASME standards (e.g., B16.9, B16.5, B16.34).

ASME B16.25 (BUTT WELD ENDS)

ASME B16.25 sets standards for the preparation of the ends of components that need to be welded together.