Search This Supplers Products:steel flangesCarbon steel pipe elbowssteel pipe teessteel pipe redcuerssteel pipe capspipe bends

Flange connection types

Flange connection can be divided into five general: that is, flat welding, butt welding, socket welding, loose sleeve, thread.

Here is a detailed description of the first four:

Butt welding

The inner and outer layers of the flange shall be welded, generally used for medium and high pressure pipelines, the nominal pressure of the pipeline is between 0.25~2.5MPa.The sealing surface of butt welding flange connection is concave and convex, the installation is more complicated, so the labor cost, installation method and auxiliary material cost are higher.

Socket welding

generally used in pipelines with nominal pressure less than or equal to 10.0mpa and nominal diameter less than or equal to 40mm.

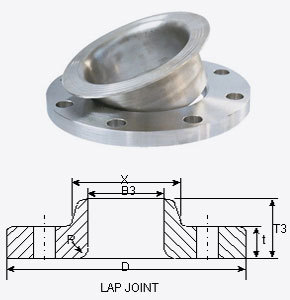

Loose cover

Generally used for the pressure is not high but the medium is more corrosive pipeline, so this kind of flange corrosion resistance, the material is mainly stainless steel.

This connection is mainly used for the connection of cast iron pipe, rubber lining pipe, non-iron metal pipe and flange valve, etc.