Search This Supplers Products:steel flangesCarbon steel pipe elbowssteel pipe teessteel pipe redcuerssteel pipe capspipe bends

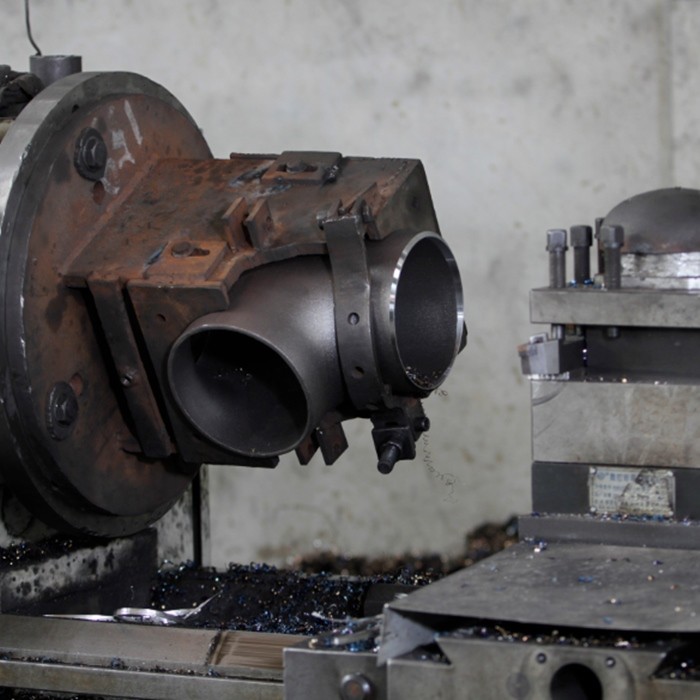

the reason why the welding Tees were fracture during working

The weld bevel on the intersecting line is mainly

formed by manual gas cutting or plasma cutting. The processing precision is not

high, the groove angle is too small, and the welding process parameters are

improperly selected, which will result in incomplete penetration. Another main reason for the quality defect of the welded tee is that

the process is wrong, the outer groove of the branch pipe is processed into the

inner groove, and the branch pipe is directly lapped on the main pipe for

welding. Incomplete penetration reduces the strength of

the weld. For pipes that transport corrosive media, as the production cycle

increases, the heat affected zone of the weld is thinned, resulting in weld

leakage. The reason for the generation of pores and slag

inclusions is that the oil, rust, moisture and other impurities in the groove

and the vicinity before welding are not cleaned, and the skin is not removed

during the welding process. In addition, during the

welding operation, the welding speed is too fast, and the welding current is

too small, which accelerates the cooling speed of the weld.